I-SENSI

Your Process Connected

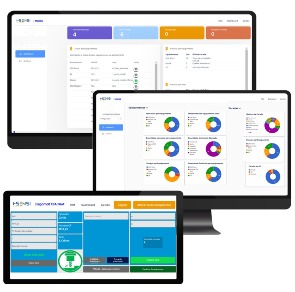

Description

We sense everything!

Data collect and analyze for shop floor optimization, process visualization, predictive maintenance, and environment monitoring with cost reduction and performance maximization.

We provide an end-to-end IoT + AI Solution, a real game-changer on the shop floor, empowering production supervisors, maintenance workers and process engineers with real time data and AI insights for process improvement.

Business Model

I-SENSI delivers a comprehensive end-to-end IoT+AI solution through a Hardware + Software as a Service (H+SaaS) model, specifically designed for SMEs or small process in large componies, transforming expensives Capex in a flexible and planable Opex.

CASE

Success Case

Challenge:

Monitor the productivity of a tool shop that supplies the automotive industry to identify the OEE of key equipment, causes of equipment downtime and increase overall productivity.

Solution:

Implementation of the digitalization of records (First_MES Platform) combined with equipment sensing (Equipment_Sensing), and the Trendz AI tool developed by I-SENSI with real-time data generation and analysis.

Results:

- Predictability of equipment usage

- Reduction of downtime by 21%

- Identification of the main causes of machine downtime

- Identification of critical parts and prevention

- Preventive analysis of part types and processes with early warnings of OEE drops

CLIENTS

MORE INFORMATIONS

Website

Customer Profile

SMEs Industrial Companies (automotive components suppliers - tier 3/4, mold and die manufacturers)

https://www.i-sensi.io

https://www.i-sensi.io

@I_sensi

@I_sensi

i-sensi-tecnologia-da-informacao

i-sensi-tecnologia-da-informacao